| Products > Waste Water Treatment (for ETP & STP ) > Aerobic Treatment >> |

|

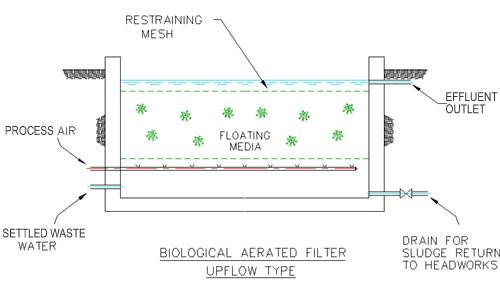

| Submerged Aeration Filter(SAF):- |

|

|

| |

| |

| |

| Introduction:- |

|

|

| |

Submerged Aerobic Filter (SAF) incorporates the advantages of Fixed Film Technology combined with Fine bubble Diffused Aeration. SAF is highly suitable for medium and low strength wastewater. Shivam design good quality submerged aerated filter to reduce the amount of BOD and ammoniacal nitrogen in settled sewage and industrial effluents. BOD removal efficiency possible of SAF reactor is 95 - 97%. |

| |

| Basic Structure :- |

|

|

| |

The SHIVAM SAF is a fabricated steel tank split into treatment cells, arranged in series. Each cell houses a number of fine bubble membrane diffusers, which are mounted below a packed rigid corrugated PVC media. |

| |

Working Principle:- |

|

|

| |

The Aerated effluent is passed via submerged media which acts as a physical support for the growth of micro organisms. The Submerged aerated filters are seeded with bacterial cultures to accelerate start-up. Air is introduced in the filter from perforated pipes, from nozzles or from fine bubble diffusers located below the media support structure. |

| |

|

| |

Applications:- |

|

|

| |

- Municipal & Domestic Sewage Treatment

- Industrial Wastewater Effluents including

- Abattoirs

- Breweries

- Chemical Processing

- Dairies

- Distilleries

- Food Processing

- Pharmaceuticals

- Textiles

- Landfill and Bioremediation

- Permanent wastewater treatment plants

- Mobile emergency response treatment units

- Temporary treatment during planned maintenance

- Propping up biologically overloaded works

- Leachate treatment

- Industrial waste treatment

- Pilot studies

|

| |

Advantages:- |

|

|

| |

- Lower Capital Cost.

- Higher BOD/ COD removal efficiency.

- Higher resistance to shock loading.

- Consistent performance.

- Lower Space/ Power Requirement.

- Quick & easy installation.

- Completely mixed and highly oxygenated discharge.

- Degradation of fats, oils and grease (FOG) .

- Non-chemical pH control.

- Protects biological secondary treatment from harmful VOCs .

- Minimal O&M requirements.

- Guaranteed system performance

- Produces high effluent qualities; tolerates variations in biological and solids loadings

- Eliminates the high headloss conditions allowing the use of deeper media beds

- Eliminates the plugging potential typically associated with BAF

- Eliminates air and water distribution problems

- No backwashes are required

- Process air blowers and low head feed pumps constitute the only major power requirement

- Minimal process monitoring is required releasing valuable operator time

- Utilizes a durable media with a long proven performance life in excess of 20 years

- No moving or serviceable parts

- Small footprint

|

| |

| |