| Products >Waste Water Treatment(for ETP & STP)>Tertiary Treatment >> |

|

| Media Fileration (PSF,DMF,MGF):- |

|

|

| |

| Pressure sand filter :- |

|

|

| |

|

| |

| Introduction:- |

|

|

| |

| Pressure sand filter is highly recommended for the removal of suspended & visible impurities like sand, dust particles & heavy metals etc.PSF is an ideal solution for the systems with high sediment, silt, sand, and turbidity. |

| |

| Basic Structure :- |

|

|

| |

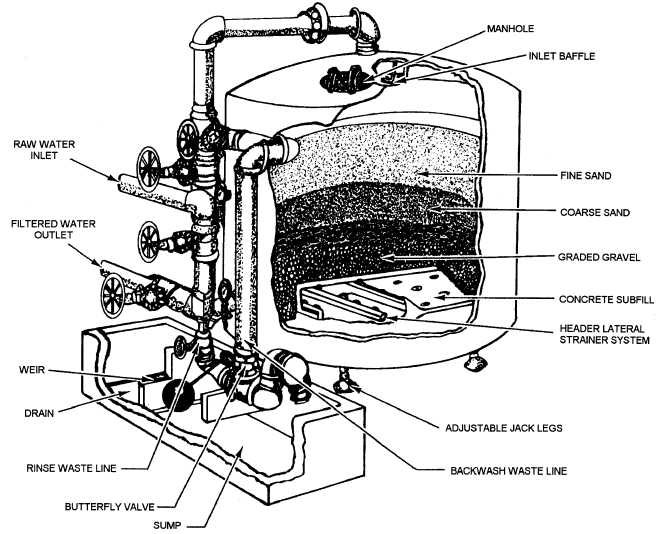

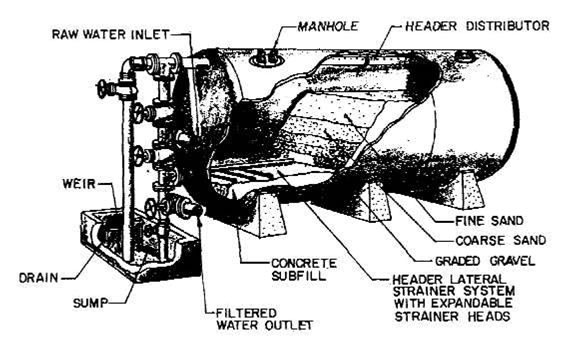

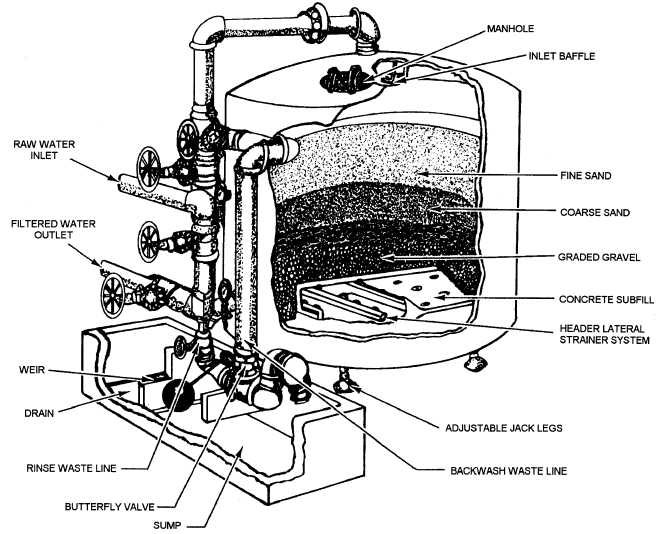

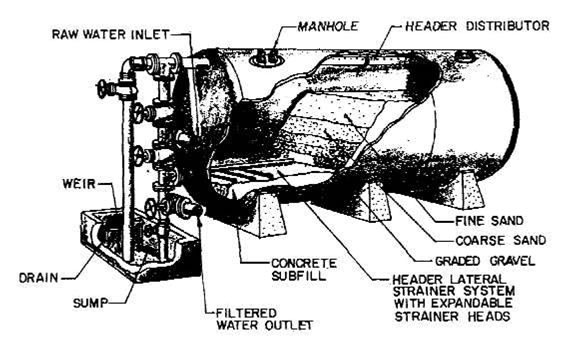

| A typical pressure sand filter consists of a pressure vessel - this could be either vertical or horizontal-fitted with a set of frontal pipe work and valves, graded sand supported by layers of graded under bed consisting of pebbles and silex, a top distributor to distribute the incoming water uniformly throughout the cross section of the filter, and an under drain system to collect filtered water. Fig shows the arrangement of a vertical and horizontal pressure sand filter. |

| |

|

|

Working Principle:- |

|

|

| |

| In sand filters water enters in the filter and percolates through the filter bed. Suspended matter present in the water comes in contact with the media particles and is trapped on the top of the bed. Followed by this, clean water comes out through the filtration nozzles and through the filter outlet. Periodically cleaning of this filter is done by backwashing. Water is introduced in the reverse direction of the service flow that is from the outlet nozzle upwards causing suspension of the turbid material in the filter bed & finally flushing out through the backwash valve. The Filter is then down rinsed & clear water is taken in the system. |

| |

Applications |

|

|

| |

- Pretreatment to all forms of Industrial water treatment

- Potable Water treatment

- Filter high quantity of water

- Thermoelectric power plants

- Irrigation & farming

- Aqua culture

- Tertiqary treatmernt

- RO pretreatment

- Swimming pool water

- Filtration of gray surface water

- Pre filtration for membrane systems

- Filtration in swimming pools

- Production of drinking water

- Treatment of waste water

- Preparation of cooling water

|

| |

Advantages |

|

|

| |

- Easy to operate

- Requires least maintenance

- Excellent filter quality at higher flow rate than conventional ones

- Low pressure drop

- Required Less Space

- A single unit elevates and separates oil

- Lifts oil any distance without the need of expensive pumps

- Maintains skimming efficiency with fluctuating fluid level

- Can be used in depths as shallow as one foot, or as deep as 100 feet

- Requires no tank modifications in most applications

- Operates in turbulent liquid using optional tail pulley cage and tether assembly

- Easy mounting and fast cleaning, with minimal maintenance

- Inverter control drive for precise operation control and safety

- Minimum Maintenance.

|

| |

| Dual Media filter:- |

|

|

| |

|

| |

| Introduction:- |

|

|

| |

| SHIVAM offer a wide range of dual media filters which includes Pressure Sand Filters and Activated Carbon Filters. All of our filters are used to remove humidity of the turbidity and organics, dechlorination, etc. These dual media filters have high dirt removal capacity of as the finest sand forms. Thick layer of coarse anthracite is provided along with these filters |

| |

| Basic Structure :- |

|

|

| |

This comprises off sand and anthracite as filtering media and polishing media respectively. Internally it is fitted with inlet distributor and a bottom collecting system. Externally, it is fitted with frontal pipe work and isolation valves. Sand is used for removing the suspended particles and anthracite removes the odor and colour etc to make the water fit for various application. Pebbles and gravels are provided to support to both the media. This filter is to be backwashed after accumulation of suspended solids, however, before carrying out the backwash, air scouring is also to be done for loosening of dirt and suspended solids. Limit for the backwash in these filers is governed by differential pressure across the filter. |

| |

Working Principle:- |

|

|

| |

Sand and anthracite is used for giving the maximum efficiency for Depth filtrations where bigger particles will settles in the anthracite layer and smaller particles are trapped in sand layer. Vessels are horizontal and vertical construction as per IS and ASME standards, Specialized designs are available for clarfier/thickner down stream applications. SHIVAM designed distribution and collection systems to ensure proper functioning of the system and operate with maximum efficiency |

| |

Applications |

|

|

| |

- Oil-wetted solids

- Solid stabilized oil droplets

- Biological flocs and waste water solids

- Precipitates and scales

- Clay and mineral particles

- Fly ash

- It also cock-up with existing applications of PSF and ACF.

|

| |

Advantages |

|

|

| |

- Dual media filters have high dirt removal capacity of as the finest sand forms.

- Dual media filters are five times more effective in removing dirt than the pressure filters.

- It also cock-up with existing benefits of PSF and ACF.

|

| |

| Multimedia Filter: |

|

|

| |

|

| |

| Introduction:- |

|

|

| |

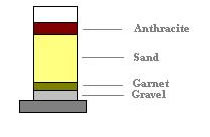

Multimedia Filter Systems also known as depth filters or turbidity filters contain two or more types of media and gravel under-bedding. The gravel is used as a support to keep smaller medias out of the distribution system and to stop channeling of water.

Our multimedia system is design for the removal of turbidity in the water caused by sand, silt, ferric iron and oxidized manganese or sulfur. They are used in applications such as chlorination filtration systems, general turbidity removal and prior to ultraviolet sterilizers or water softeners.

Different grade of sand with definite size are the specialty of these filters. These are vertical and horizontal type with specialized design of distribution and collection systems to ensure proper functioning of the system and operate with maximum efficiency. Coarse, Quartz sands are used for this and some cases Garnet is also use as the media of filtration.

|

Working Principle:- |

|

|

| |

Multimedia filtration is a proven design concept; the coarse media layers in the top of the tank trap large particles, and successfully smaller particles are trapped in the finer layers of media deeper in the bed. The result is a highly efficient filtering since removal takes place throughout the entire bed. Multimedia filters typically remove particles 5 to 15 microns in size or larger as opposed to a conventional single media sand filter which removes 30 micron or higher.

We use Triple Filtration Media for maximum removal: Anthracite, Sand and Garnet.

|

| |

Applications |

|

|

| |

- Pretreatment to all forms of Industrial water treatment

- Potable Water treatment

- Filter high quantity of water

- Thermoelectric power plants

- Irrigation & farming

- Aqua culture

- Tertiqary treatmernt

- RO pretreatment

- Swimming pool water

- Filtration of gray surface water

- Pre filtration for membrane systems

- Filtration in swimming pools

- Production of drinking water

- Treatment of waste water

- Preparation of cooling water

|

| |

Advantages |

|

|

| |

- Easy to operate

- Requires least maintenance

- Excellent filter quality at higher flow rate than conventional ones

- Low pressure drop

- Required Less Space

- A single unit elevates and separates oil

- Lifts oil any distance without the need of expensive pumps

- Maintains skimming efficiency with fluctuating fluid level

- Can be used in depths as shallow as one foot, or as deep as 100 feet

- Requires no tank modifications in most applications

- Operates in turbulent liquid using optional tail pulley cage and tether assembly

- Easy mounting and fast cleaning, with minimal maintenance

- Inverter control drive for precise operation control and safety

- Minimum Maintenance.

|