| Products > Water treatment Equipment > Filtration System >> |

|

| Dissolved Air Flotation (DAF):- |

|

|

| |

|

| |

| Introduction:- |

|

|

| |

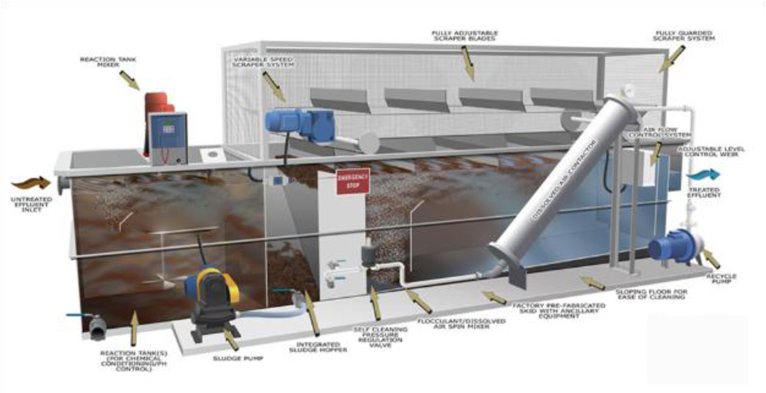

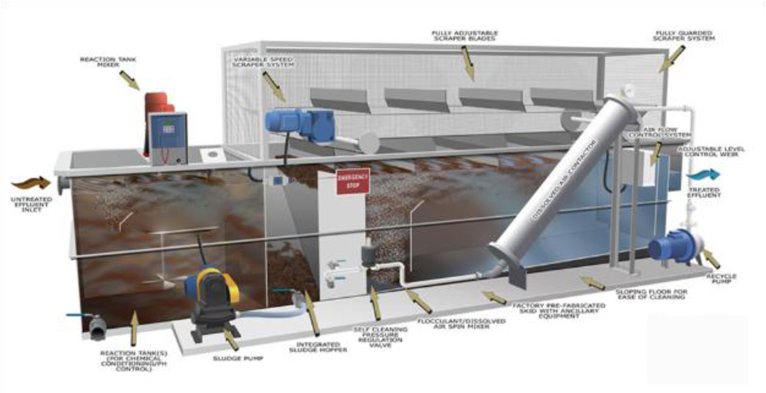

| DAF is a fast and highly efficient method for removing turbidity, color, suspended solids and other contaminants from water using air bubbles. These specially created air bubbles are first mixed with wastewater, attach themselves to solids present and then separate them by flotation leaving clarified water behind. DAF has become widely accepted for use in potable water treatment, municipal wastewater as well as a variety of industrial applications |

|

| |

Working Principle:- |

|

|

| |

Dissolved Air Flotation (DAF) is an efficient flotation method for water clarification.

Dissolved Air Flotation (DAF) is a process for the removal of fine suspended material from an aqueous suspension. The term "flotation" indicates something floated on or at the surface of a liquid.

The DAF provides the energy for effective flotation in the form of extremely fine air bubbles, which become attached to the suspended material to be removed. This attachment of bubbles to the particle "reduces" the density of the particle resulting in increased buoyancy, thus effecting flotation. Chemical conditioning is often used to increase the effectiveness of the dissolved air flotation process.

The most reliable and positive method of producing bubbles of the proper size is to dissolve air into water under pressure and to then reduce the pressure of the solution. As the pressure is reduced, the air comes out of solution in the form of micro bubbles.

|

- Wastewater is pretreated with chemicals.

- Treated influent is fed to DAF unit.

- Recycle is drawn off effluent line and is sent through the air dissolving system and then sent back into the DAF.

- Air is released from the recycle flow and the bubbles help to float solids in the DAF tank.

- Float is skimmed from the top of the tank.

- Clear effluent flows out of the unit.

|

| |

Applications:- |

|

|

| |

Dissolved air flotation is best applied to remove materials that normally settle slowly, persist by remaining in suspension, or have a tendency to float.

- Aircraft Maintenance

- Algae Removal

- Automotive Industry

- Bakery Waste

- Ballast Water

- Canning

- Chemical Processing Plants

- Fiber Recovery

- Heavy Metal Recovery

- Latex

- Meat Packing

- Paint Waste

- Pet Foods

- Pharmaceutical

- Potato Processing

- Poultry Processing

- Prepared Foods

- Pulp and Paper Mills

- Refineries

- Rendering

- Seafood Processing

- Slaughter House

- Tank and Truck Cleaning

- Tanning

- Textiles

- Vegetable Oil

|

| |

Advantages:- |

|

|

| |

- Initial construction costs are reduced 30-50% as compact DAF clarifiers are less costly to construct and install than larger settling basins.

- Further savings are achieved when the plant is enclosed in a building as less area is required for DAF.

- Chemical costs are reduced as flotation in general requires less chemical pretreatment to form a light, small floc.

- DAF is ideal for treatment plants in remote locations or with limited available area.

- Continuous operation

- Application versatility

- Ease of operation, requires minimal attention

- Simple, durable design for low maintenance and long life

|