| Products > Water Treatment Equipment > Membrane Based >> |

|

| Ultrafiltration (UF):- |

|

|

| |

|

| |

| Introduction:- |

|

|

| |

| Ultrafiltration (UF) is a pressure-driven barrier to suspended solids, bacteria, viruses, endotoxins and other pathogens to produce water with very high purity and low silt density. Typically, ultrafiltration will remove high molecular-weight substances, colloidal materials, silt (SDI), and organic and inorganic polymeric molecules. It serves as a pretreatment for surface water, seawater, and biologically treated municipal effluent before reverse osmosis and other membrane systems. SHIVAM’s Ultrafiltration is a separation process using membranes with pore sizes in the range of 0.1 to 0.001 micron. |

| |

|

| |

| Typical Ultra Filtration Membrane separation Chart for Different feed |

| |

|

| |

| Typical Membrane separation Chart for Different feed |

| |

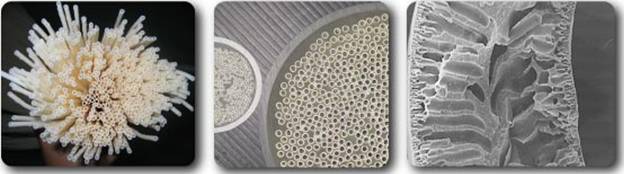

SHIVAM’s ULTRAFILTRATION MEMBRANE’s STRUCTURE’s CONFUGRATION:

Low molecular-weight organics and ions such as sodium, calcium, magnesium chloride, and sulfate are not removed. Common polymeric materials used in UF include: Polysulfone (PS), Polyethersulfone (PES), Polypropylene (PP), or Polyvinylidenefluoride (PVDF). Although these materials can be blended with hydrophilic agents, they can reduce the membranes ability to be cleaned with high strength disinfectants such as hypochlorite that impacts removal of bacterial growth. |

| |

|

| |

Working Principle:- |

|

|

| |

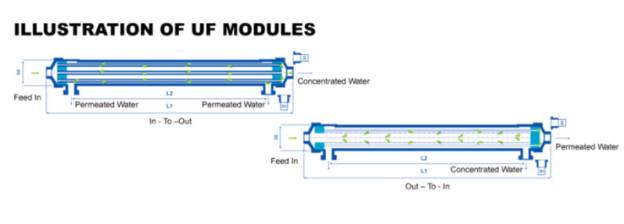

Shivam designs Ultrafiltration system for in-out as well as out-in flow configuration.Ultrafiltration is a technique for separating dissolved molecules in solution on the basis of size which means that molecules larger than the membrane pore size rating will be retained at the surface of the membrane. The accumulation of retained molecules may form a concentrated gel layer. The impact of gel-layer formation is that it can significantly alter the performance characteristics of the membrane. This is commonly called concentration polarization. Fundamentally, the gel layer will limit filtrate flow rate and any increase in pressure will have no beneficial effect. Controlling and reducing the impact of gel-layer formation has been achieved with reversal of flow with treated water. |

| |

|

| |

Applications:- |

|

|

| |

- Dialysis and other blood treatments

- Concentration of milk before making cheese

- Fractionation of proteins

- Clarification of fruit juice

- Recovery of vaccines and antibiotics from fermentation broth

- Laboratory grade water purification

- Wastewater treatment

- Drinking water disinfection (including removal of viruses)

- Removal of endocrines and pesticides combined with Suspended Activated Carbon pretreatment

- proteins can be separated in whey for the production of whey protein concentrate (WPC)

- milk can be concentrated prior to cheesemaking at the farm level

- apple juice and wine can be clarified

- waste treatment and product recovery is possible in edible oil, fat, potato, and fish processing

- fermentation broths can be clarified and separated

- whole egg and egg white ultrafiltration as a preconcentration prior to spray drying

- Industrial applications include power generation

- food and beverage processing

- biotechnology

- semiconductor manufacturing

- In industry to separate suspended solids from solution

|

| |

Advantages:- |

|

|

| |

- Flexibility:

Available in pressurized or submerged configurations suitable for multiple plant requirements.

- Superior fiber strength:

Employs a robust membrane fiber that ensures long term integrity.

- Ease of Installation:

Stand-alone pre-packaged units and components for larger projects have been designed to be assembled in the factory to the greatest extent possible to simplify installation.

- Consistent water quality from any source water

- Effective pathogen removal

- Lowest lifecycle cost through optimized energy and chemical use

- Compact design resulting in small system footprint.

|