| Products > Water Treatment Equipment > Membrane Based >> |

|

| Electrodeionisation(EDI):- |

|

|

| |

|

| |

| Introduction:- |

|

|

| |

Electrodeionisation or EDI, is a continuous and chemical-free process of removing ionized and ionizable species from the feed water using DC power. EDI is typically used to polish reverse osmosis (RO) permeate and to replace conventional mixed bed ion exchange, which eliminates the need to store and handle hazardous chemicals used for resin regeneration and associated waste neutralization requirements. |

| |

| Basic Structure :- |

|

|

| |

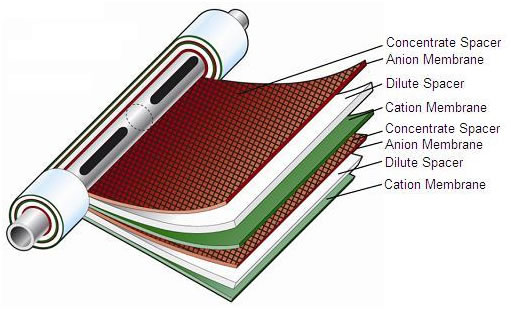

| The Shivam EDI module utilizes a unique, leak free, low maintenance spiral wound design containing membrane (see below) and ion exchange resins, sealed in a high-strength fiberglass reinforced plastic (FRP) pressure vessel. Shivam EDI modules optimize performance, maintain continuous product quality and can produce up to 18 M -cm high-purity water with high silica and boron rejection. |

| |

|

| |

Working Principle:- |

|

|

| |

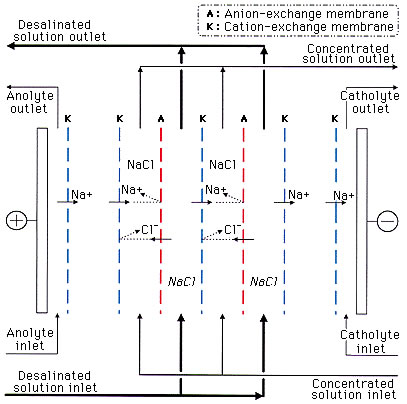

Our Continuous electrodeionisation modules utilize ion exchange resins primarily as a bridge to allow electric current to pass through the electrodeionisation cell. This allows us to operate the modules without any brine injection or concentrate recycle. Additionally, the ion exchange resins are used to 'polish' the purified water stream by removing minute quantities of silica, carbon dioxide and other contaminants. The ion exchange resins are continually being regenerated by the dissociated hydrogen and hydroxyl ions that have been created by the electric current. Electrodeionization utilizes no chemical regenerants and creates no hazardous wastes. |

| |

|

| |

Applications:- |

|

|

| |

EDI is useful for any application that requires constant and economic removal of water impurities without using dangerous chemical. Some examples are:

- Reuse of residual water in food and beverages industry

- Chemical production

- Biotechnology

- Electronics

- Cosmetic

- Laboratories

- Pharmaceutical industry

- Boiler Feed Water

- Reduction of ionizable SiO2 and TOC (total organic carbon)

- Food Processing.

- Semiconductors

- Waste Water Treatment

- Dairies

|

| |

Advantages:- |

|

|

| |

- No Leakage:

Shivam EDI modules are reliably sealed with high pressure top and bottom end caps eliminating leakage problems commonly associated with plate and frame design.

- Quality Control:

Each EDI module is performance and pressure tested prior to leaving our factory to ensure trouble free start-up and operation.

- Low Maintenance:

Unlike plate and frame EDI systems, Shivam EDI modules do not require tightening of nuts and bolts at installation or the retorquing of bolts on an ongoing basis to prevent leaks.

- Light Weight Modules, Modular, Easy Access Designs: The Shivam EDI modules result in very modular systems that allow easy access and the light weight modules are easy to work with, no special lifting devices are required. Each module comes complete with an individual permeate sample port.

- Cost Effective: The spiral wound Shivam EDI modules allow system integrators to build systems that have both lower capital and operating costs when compared to plate and frame EDI devices and is truly a cost-effective replacement for conventional mixed bed ion exchange.

- Removes the need for chemicals

- Reduced effluent volumes.

- Easy to service.

- Consistent water quality.

- Small footprint. – Can be configured on the same skid as the Reverse Osmosis system.

- The system can be Validated to USP & EP Requirements.

- Can be configured as a sanitary system.

- Safe Process

- Hot Water Sanitisable if correct stack configuration is selected.

|

| |

| |