"Water… water… everywhere, Nor any drop to drink……. "

Desalination is the natural continuous process, which is essential for the water recycle. Precipitation, such as rain or snowfall on ground, which finally flows either in to the sea or goes back to the atmosphere through evaporation or percolates in the sub-soil is a process of natural desalination. |

SWTPL with vivid innovation and development has created different designs and concepts for Desalination. All our systems are compact by eliminating the high investment on civil infrastructures. The cost of implementing the Desalination Plant is concentrated towards technology, plant and machinery rather than dumping it on gigantic civil structures.

Shivam has focused its expertise on compactness and readily available complete systems, which saves the essential factor of time. Technology is other primary core sector of SWTPL, which allowed us to be different form our competitors.

We differ in technology, structuring layout, compactness, operation cost and in deliverance.

Desalination Process:-

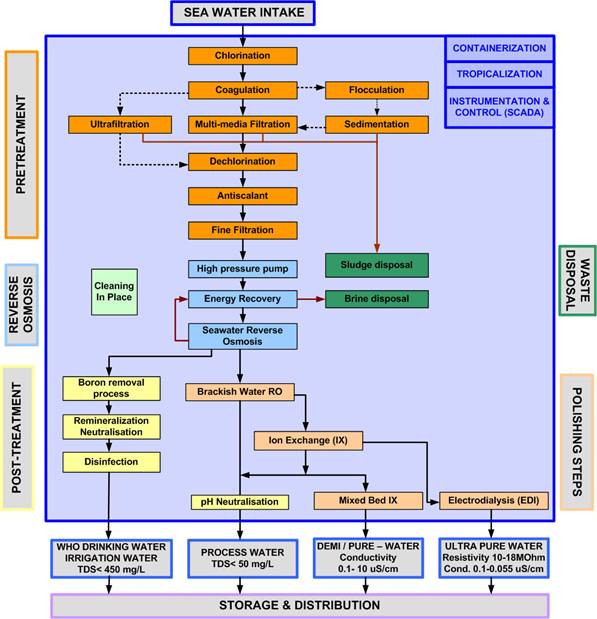

There are basically three main treatment elements in the desalination process: pretreatment, reverse osmosis, and post-treatment.

Pretreatment:-

Pretreatment must be rigorous to remove sediment, organic matter and other microscopic particles to ensure efficient reverse osmosis operations.

Seawater entering the plant is first treated with chemicals to allow eventual settling of particles. It then goes through traveling screens that filter out shells and other larger debris. The screened water then goes through settling chambers. Similar to a traditional surface water treatment process, particles in the conditioned water clump together and settle out.

The next step in pretreatment is sand filtration, where smaller particles are filtered from the water. Next, diatomaceous earth filters eliminate microscopic materials before the water passes through cartridge filters, the last barrier before the RO process.

Reverse Osmosis:-

Reverse osmosis is what distinguishes a desalination plant from a traditional surface water treatment plant. During RO, high pressure forces the pretreated water through semi-permeable membranes, separating saltwater from freshwater and leaving salt and other minerals behind in a salty solution.

The size of each RO membrane pore is about 0.0001 microns, which is about 1/100,000th the diameter of a human hair.

Post-treatment:-

After the RO treatment as shown in the below Flow chart as per requirement of Treated water additional equipments such as DM plant.MB units,Chlorination,UV treatment is given.For drinking purpose treated water is than pumped to the regional facilities site, where the desalinated seawater is blended with treated drinking water from other supply sources before being delivered to utility. |