| Products > Waste Water Treatment (for ETP & STP ) > Aerobic Treatment >> |

|

| Sequential Batch Reactor(SBR):- |

|

|

| |

|

| |

| Introduction:- |

|

|

| |

Sequencing batch reactors (SBR) or sequential batch reactors are industrial processing tanks for the treatment of wastewater. SBR reactors treat biosolids, sewage, sludge or other output from aerobic or anaerobic digesters in "batches." |

| |

| Basic Structure :- |

|

|

| |

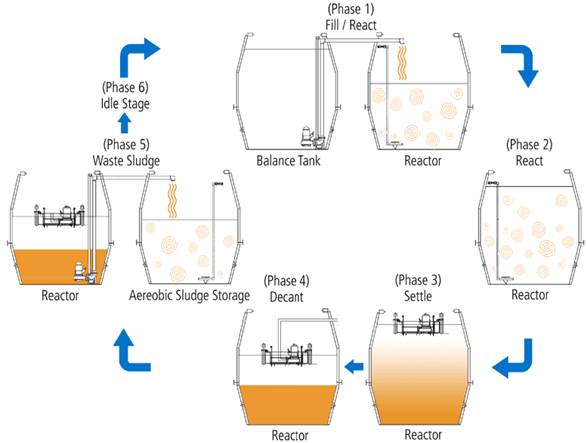

The Sequence Batch Reactor (SBR) cleans the wastewater in one or more batch reactors according to a predetermined sequence of operations. The system performs equalization, aeration and clarification in a single batch reactor.

Usually the Pipelife SBR system consists of at least two tanks. In this kind of configuration the first tank – the settlement tank – is used to retain the non-solvent particles. Because of their physical characteristics the non-solvent particles are discarded at the bottom of the settlement tank. The rest of the wastewater is conveyed to the second reactor by the pump on the reactor unit – the Swimmer Unit into the second tank – the SBR. |

| |

Working Principle:- |

|

|

| |

The wastewater treatment is essentially accomplished by the equipment mounted on the SBR’s swimmer unit. The unit floats on the water in the reactor. Due to its floating nature, the pumps and equipment that it hosts stay in optimal position at the top of the water level.

When the second tank – the SBR – is filled, the water treatment of the respective batch begins. The aerator mounted on the Swimming unit pumps air into the reactor tank. The air is necessary for the biological part of the cleaning process. Additional components can be pumped into the wastewater in order to remove chemical residues.

After the wastewater treatment cycle is finished, the cleaned water is pumped out of the system and safely discharged into the environment. Afterwards the SBR system is immediately ready to start the cleaning of the following batch. |

| |

|

| |

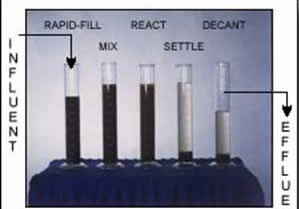

| SBR results at our lab. |

|

Applications:- |

|

|

| |

• Domestic Applications:–

a) Municipal

b) Resorts

c) Institutions

• Industrial Applications:–

a) Chemical/ Petrochemical

b) Leachate

c) Food

d) Tobacco

e) Paper & Pulp

f) Dairy

g) Textile

h) OCPSF (organic chemicals, plastics ,Synthetics and Fibers)

i) Sugar

|

| |

Advantages:- |

|

|

| |

- It is true sequencing batch system and able to provide consistent effluent quality to desired limits.

- SBR is designed to minimize operation and maintenance cost all equipments accessible from side the plant eliminating the need to dewater. As –

• Floating aerators

• Submersible mixers

• Effluent pumps

- Easy installation - packaged option available.

- Reduced sludge volumes from integral aerobic digester.

- Automated control minimizes operator attendance.

- Ideal for sensitive applications

- High/low flow modes to enable both storm water processing and extended periods of low demand.

- Full access to PLC software available to end user allowing on site adaptation to long term increases or decreases in flows and loads. Software upgrades available.

- Pre-screened effluent prevents pump blockages.

- Minimal visual impact - eliminates settlement tanks.

- Cost effective operation - no media costs and accurate control of retained activated sludge

- Excellent performance meeting environmental specifications.

- Automated control.

- Remote monitoring and process control capability.

- Accommodation of load variations without degradation of effluent.

- Flow equalization and balancing.

- Cycle sequencing can be configured to ideally match batch industrial processes and save on upstream balancing.

- Return Activated sludge piping is eliminated.

- Lowest electrical operating cost- Electricity consumption per Kg BOD destroyed is around 1.1 KW as compare to other processes (1.7 KW with conventional activated sludge process).

|

| |

| |