|

||

|

||

|

||

|

||

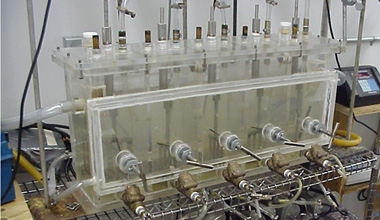

| A continuously fed, compartmentalized reactor that reverses its flow in a horizontal manner. This system is developed without the requirement of elaborate gas-solids-separator and feed-distribution systems. Effluent recycling is not required, but mixing is necessary to obtain a sufficient biomass/substrate contact. This process is known as the anaerobic migrating blanket reactor (AMBR). | ||

|

||

| The AMBR is similar to the anaerobic Baffled Reactor (a series of unmixed compartments) with the added features of mechanical mixing in each stage and an operating approach designed to hold the sludge in the system without resort to packing or settler for additional solids capture. In the AMBR, the last stage is left unmixed to maximize settling, and the feed and effluent points are alternated periodically to reverse the movement of sludge through the reactor. The last stage becomes mixed when the flow is reversed. |

||

|

||

|

||

|

||

|

||